Explore EOX Renew

-

Energy-efficient and ultra-smooth belt drive made in Germany

-

Standard-included regenerative drive to recapture electricity

Standard-included regenerative drive to recapture electricity

The small diminutive inverter, placed directly in the shaft head, reduces the overall energy consumption for propulsion of the cabin by converting the braking energy into electrical energy which is then fed back into the building’s electrical grid.

-

Smart sensors supporting preventive maintenance and passenger safety

Smart sensors supporting preventive maintenance and passenger safety

Amongst several detection sensors and safety circuits, EOX Renew also features an accelerometer in the door drive that collects data on speed and the vertical and horizontal movements of elevator door and cabin. Movement patterns are constantly analysed to anticipate potential incidents before they occur.

-

Slim and compact controller cabinet

Slim and compact controller cabinet

The low voltage state-of-the-art controller is integrated in a size-reduced cabinet with flexible location positioning. It’s easy to install and to integrate in the building, for example in the wall next to the top landing.

-

Cabin design with quality materials and large variety of wall colours

Cabin design with quality materials and large variety of wall colours

The broad design collection for EOX Renew includes durable and long-lasting wall finishes, various ceiling and mirror options, and the standard 7″ multimedia screen in the cabin. It offers everything you need to elegantly integrate the new elevator into your building’s look and feel.

-

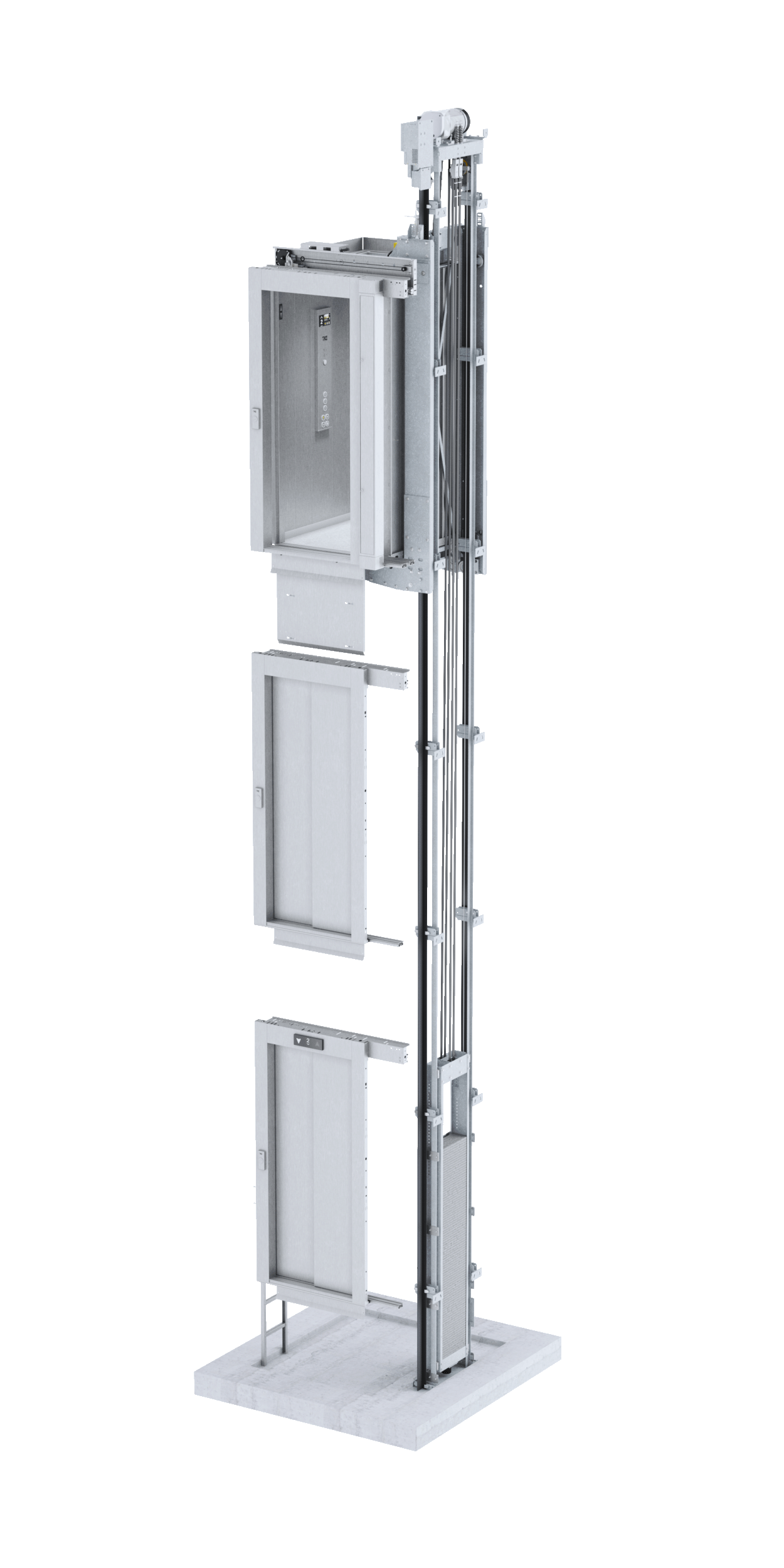

Space-saving cantilever design for maximum flexibility

Space-saving cantilever design for maximum flexibility

EOX Renew features an ultra-compact cantilever frame design with cabin roller guides. Total flexibility in the positioning of the traction system, both on the rear wall and on the sides, allow the maximum utilisation of space even in the tightest conditions. All the mechanical components in the shaft (counterweight, guiderails etc.) are arranged on a depth of just 25 cm. The robust and compact, yet very manoeuvrable design, makes it easy to transport the elevator materials even when having to pass through narrow corridors.

-

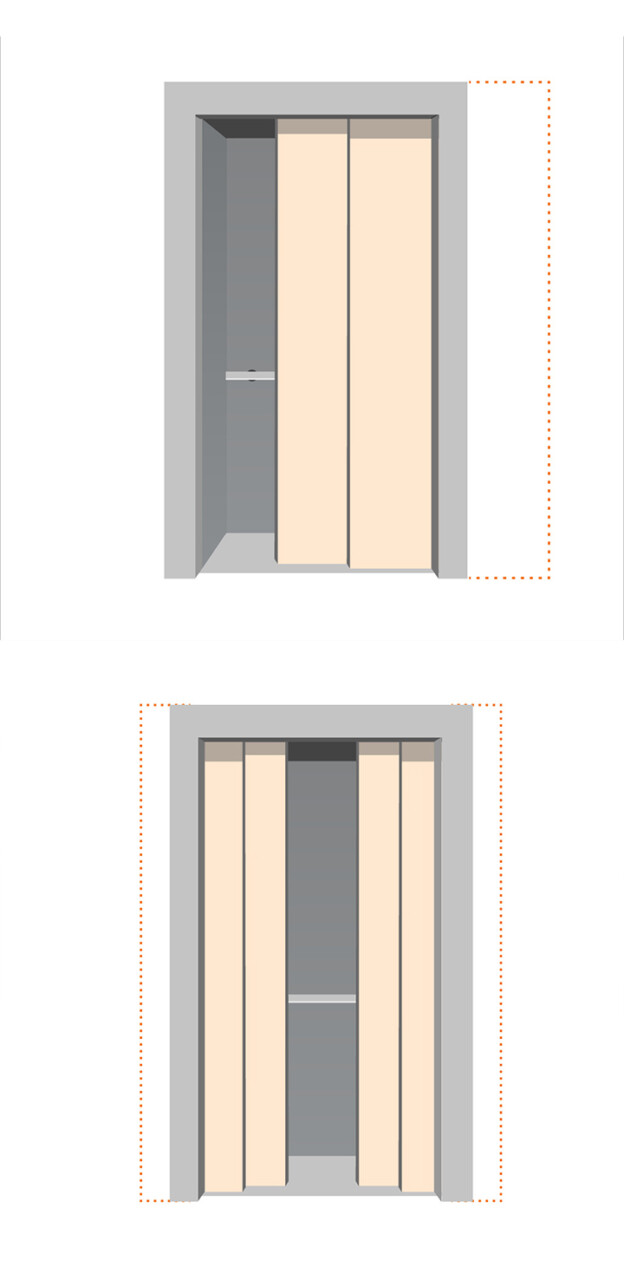

Lateral or central opening doors with flexible positioning

Lateral or central opening doors with flexible positioning

Wide range of automatic doors of proven quality with side or central opening to adapt even to the most challenging configurations. Flexible positioning to the millimetre minimises the impact on the landing layout and allows the reutilisation of door openings when replacing an old elevator.

-

Broad choice of landing operating panels and indicators

Broad choice of landing operating panels and indicators

The Series 30 landing operating panels and indicators offer a slim and sturdy design, ideal when space is limited on floor landings. The sleek and modern Series 50 holds more configuration options including an integrated display. Both series can be combined with the stainless steel Moon series COPs with 7″ multimedia display as standard.

-

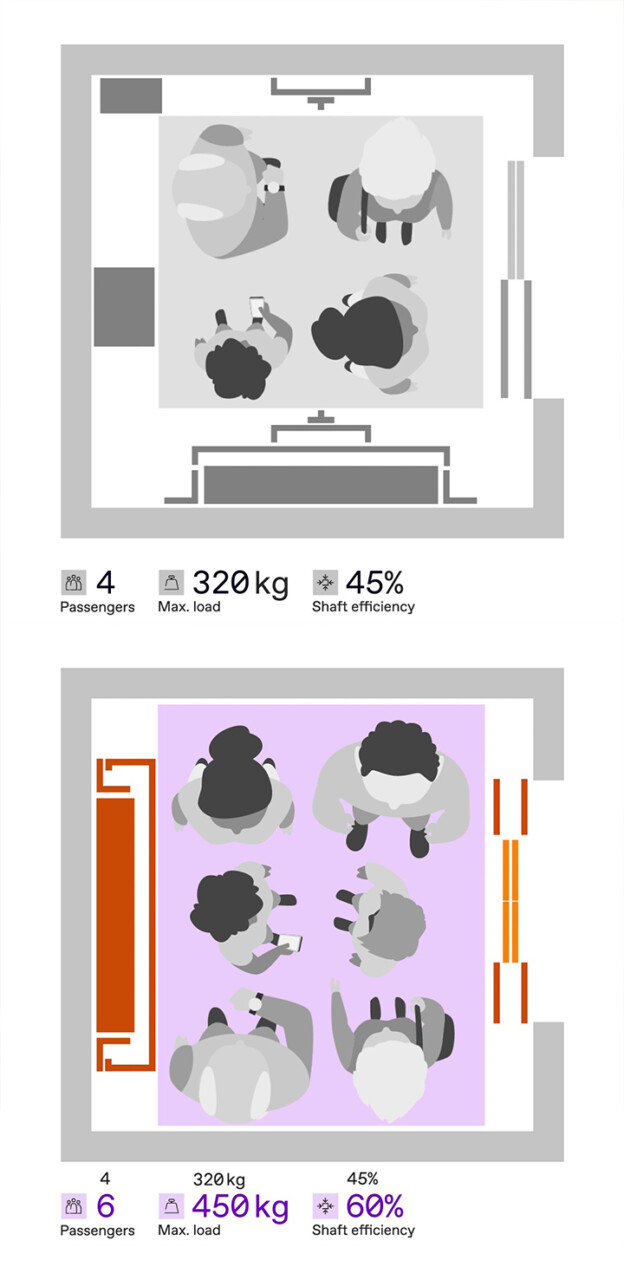

Superior shaft efficiency achieves larger cabins in same shaft

Superior shaft efficiency achieves larger cabins in same shaft

EOX Renew’s ultra-compact design maximises the utilisation of the shaft space, fitting bigger cabins with up to double the number of passengers in existing shafts.

-

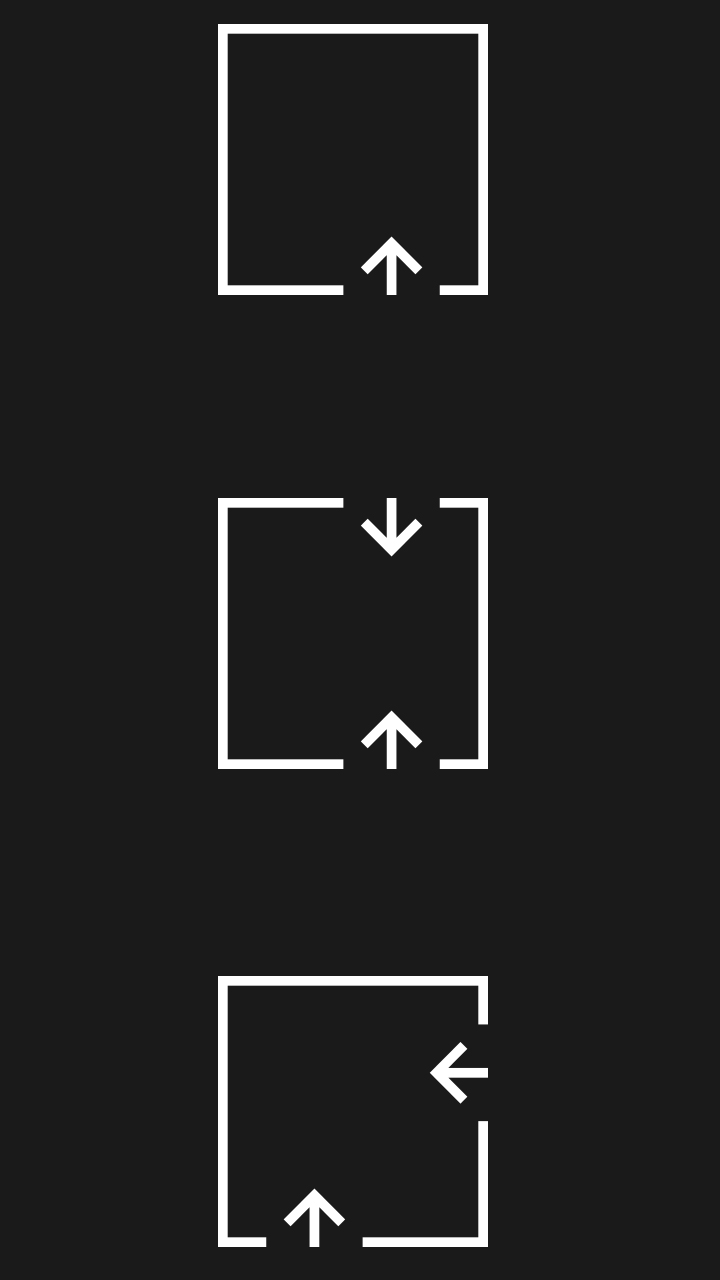

Full range of entrance configurations available: single, double 180° or 90°

Full range of entrance configurations available: single, double 180° or 90°

Maximum entrance versatility to solve even the most complex architectural accessibility challenges thanks to the option of double entrance at 180° or “around the corner” 90°.

-

Quick and easy to install with TKE’s scaffoldless method

Quick and easy to install with TKE’s scaffoldless method

With our certified scaffoldless installation method, the cabin structure is used as a working platform to safely climb the elevator shaft while installing the elevator components. The compact, modular and light design with pre-assembled components, together with the careful site preparation of TK Elevator’s expert installers, will achieve renewed accessibility in your building in less than two weeks.