The recipe of EOX Renew is based on two main ingredients: The expertise and experience from more than 60 years of TK Elevator’s history in designing and manufacturing elevators in Europe for Europe. And a fundamental understanding about the mobility needs in older buildings gathered from closely listening to our customers. The resulting product makes no compromise on the required flexibility and freedom of choice. Here’s how:

Why eox renew can flexibily adapt to your bulding

A perfect-fit design principle

EOX Renew makes of use of a special elevator design principle called the “cantilever frame”. Instead of a cabin that is directly attached to the traction system and “towed” up and down via guiderails on two sides, the EOX Renew cabin sits on a carrier frame that “holds” it from underneath and requires guiderails only on one side.

For the “maximum flexibility” promise of EOX Renew this is a perfect fit:

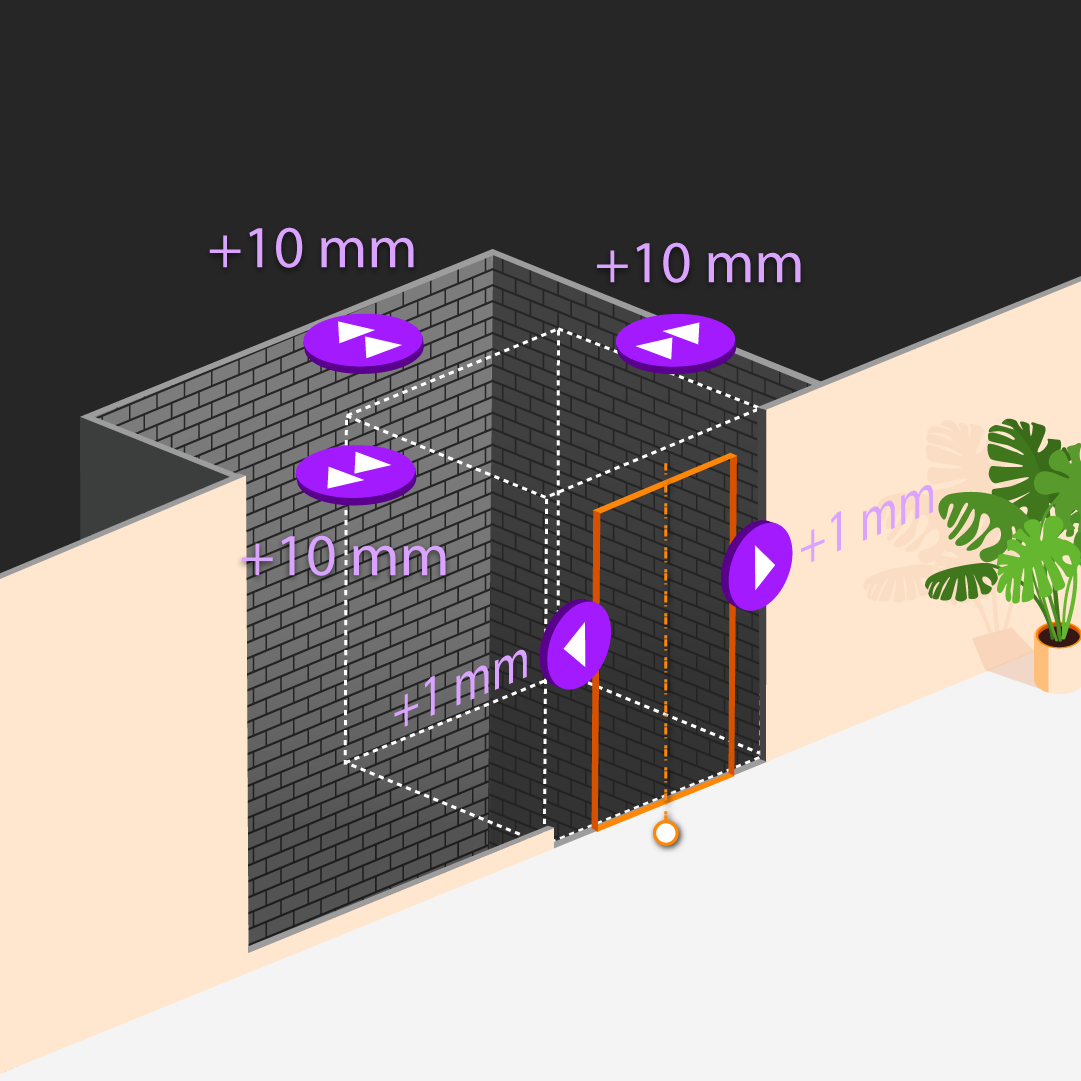

Cabin dimensions can be expanded in 10 mm steps

The cabin door position can be moved in 1 mm steps

Up to two doors can be placed around the three sides

Built-in freedom of choice

Entrance versatilityTo take the best way through and up a building, EOX Renew literally opens all doors. Beyond the common single entrance and 180° double entrance with doors opposite each other, it also offers a 90° double entrance option. If your “route to mobility” has to go around the corner, EOX Renew will lead the way.  Variable fixtures positioningAll landing operating panels and indicators available for EOX Renew offer flexible positioning. They can be installed directly on the shaft door frame in the elevator landings, or be positioned on the surrounding wall. The first option is the most space-efficient and easiest to install, whereas wall placement is preferred when existing lead-through openings from a previous elevator can be used.  Unrestricted cabin layoutUnlike most standardised elevators, EOX Renew does not require cabin components like the operating panel, the handrail and the mirror to follow a certain placement logic. This way, double entrance cabins can always be configured to exactly match the needs for ideal passenger flow. |

Space-saving engineering

Super-compact traction systemThe question whether an elevator is a space saver or not, is answered behind the elevator cabin: in the shaft. There, EOX Renew manages to tightly arrange all the technical gear within a depth of just 25 centimetres, always leaving the majority of shaft space for the cabin.  Ultra-slim controller cabinetThe controller cabinets of old elevators are sometimes big enough to fill a room. The “elevator brain” of EOX Renew comes in a such a small cabinet, that finding a space or niche for it will not pose a challenge in any building. |